Production Orders

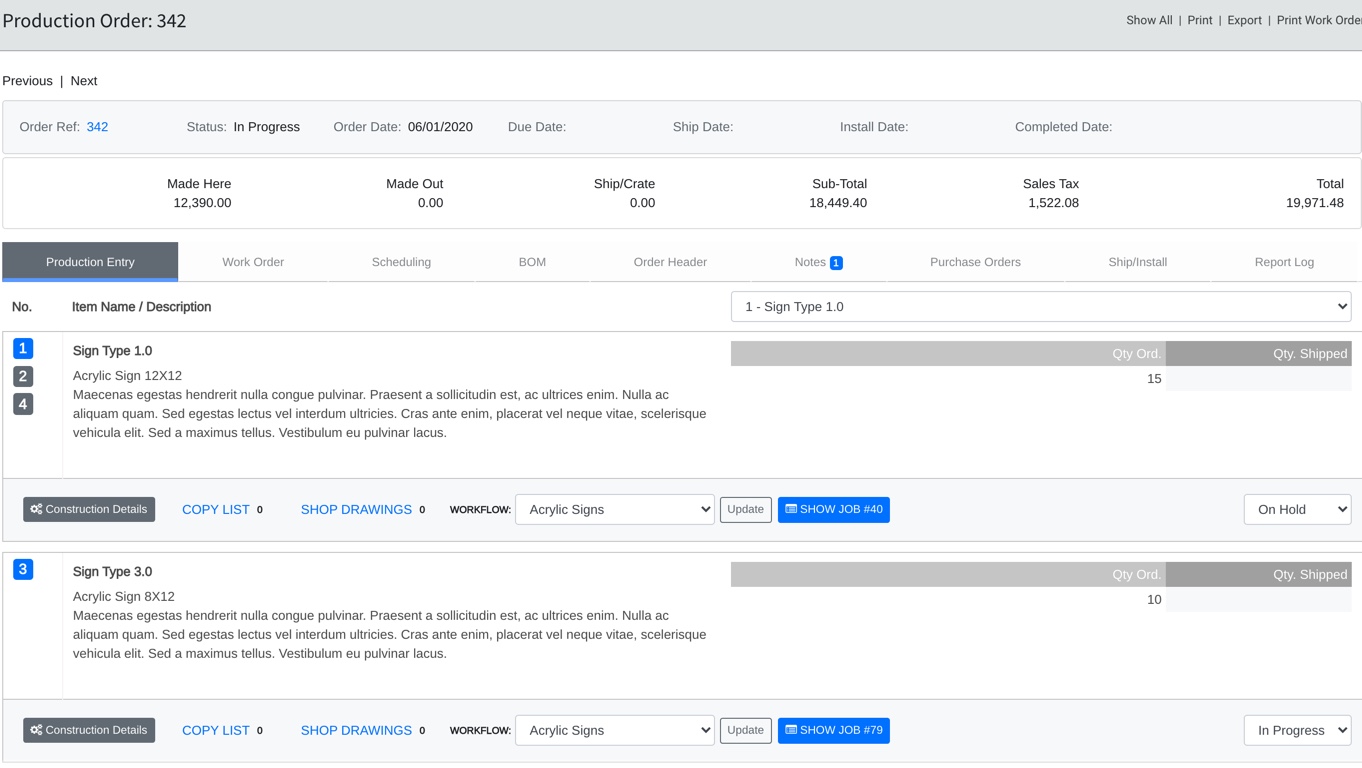

Production Orders (or Orders in Production) are essentially Sales Orders that have been submitted to the shop for building, construction, assembly, or fabrication. Production Orders are optional and used to track shop orders and can include some or all line items from within the sales order. Orders in Production have the same numbering as their sales order companion. They serve as the hub for all of the activity that takes place within the order while being fabricated.

Common activities that typically take place in the Production Order are:

- Users can assign workflows to line items.

- Users can group line items with identical workflows to create bundled jobs.

- Jobs can be created to schedule line items for production.

- Users can easily schedule some or all line item jobs in production.

- Users can track the completion of jobs by the department.

- Users can ship complete or partial products.

- Users can access corresponding Purchase Orders and mark them received from within the Production order.

Note: Service items (non-tangible professional services such as installation, repairs, site surveys, etc.) are exempt from production orders and need to be further managed in the sales order.